Company Overview

FIBC Silvassa is a leading Indian FIBC Bags Manufacturer and global supplier of FIBCs (Jumbo Bags), PP Woven Bags & Fabrics, and BOPP Bags. Headquartered in Silvassa, India, we serve international markets including the USA, Canada, Europe, Australia, and beyond. With decades of industry experience, our privately owned company focuses on quality, innovation, and customer satisfaction to consistently meet global standards.

Our Machinery & infrastructure

Our manufacturing process ensures consistent quality and performance in every FIBC bag we produce.

1.Extrusion (Tape Production)

- High-output extrusion lines for PP/HDPE tape production with uniform denier control.

- Tape Plant: LOHIA Starlinger Model-450 kg/hr Model 1400Hs , 1200Hs

Features: Energy-efficient extruders, online width & thickness monitoring

Output Range: 700-900 denier tapes - Auto Dosing Unit: Automated masterbatch feeding for consistent coloring

- Air Compressors:

5 HP 10 HP (Reciprocating)

30 HP (Screw Typej-Continuous air supply for high-demand operations - Air Receiving Tank: 1 m³ for air pressure stabilization across plant

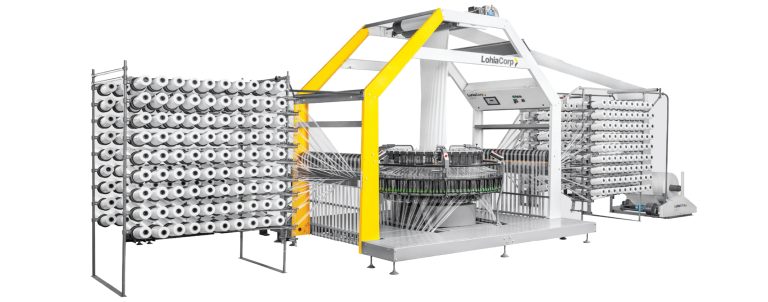

2.Looms

- Automated looms with consistent warp/weft control for high-strength fabric.

- Circular Looms:

- Models: LSL 620 (6-shuttle), LSL 8 (8-shuttle)

- Fabric Width: 91–140 cm (tubular)

- Output: Up to 120 m/hr

- Flat Looms (Webbing & Tie):

- Models: 4/85, 2/65, and Tie-specific looms

- Use: Loop/belt/tie webbing production

3.Webbing Unit

- Heavy-duty narrow fabric machines for lifting loops and belts.

- Webbing Machines:

- 4 Machines × 4 Heads (16 Heads total)

- Type: Needle loom-based narrow fabric weaving

- Output: 45–60 meters/hour per head

- Material: High-tenacity polypropylene multifilament yarns

- Application: Corner loops, cross loops, belts, safety stitching

4.Multifilament

- Specs: Denier range 300–3000, capacity up to 450 kg/hr, PLC controlled, and energy-efficient drive.

- Functions: Spinning, drawing, and winding high-tenacity multifilament yarns.

- Uses: Ideal for FIBC bags, PP woven fabrics, industrial ropes, and technical textiles.

5.Twisting Machine

High-speed operation, PLC-based control, multiple spindle setup, energy-efficient design.

Functions: Twisting multifilament yarns for better ply strength, evenness, and performance.

Uses: Essential for FIBC stitching yarns, PP woven bags, ropes, industrial sewing threads, and technical textiles.

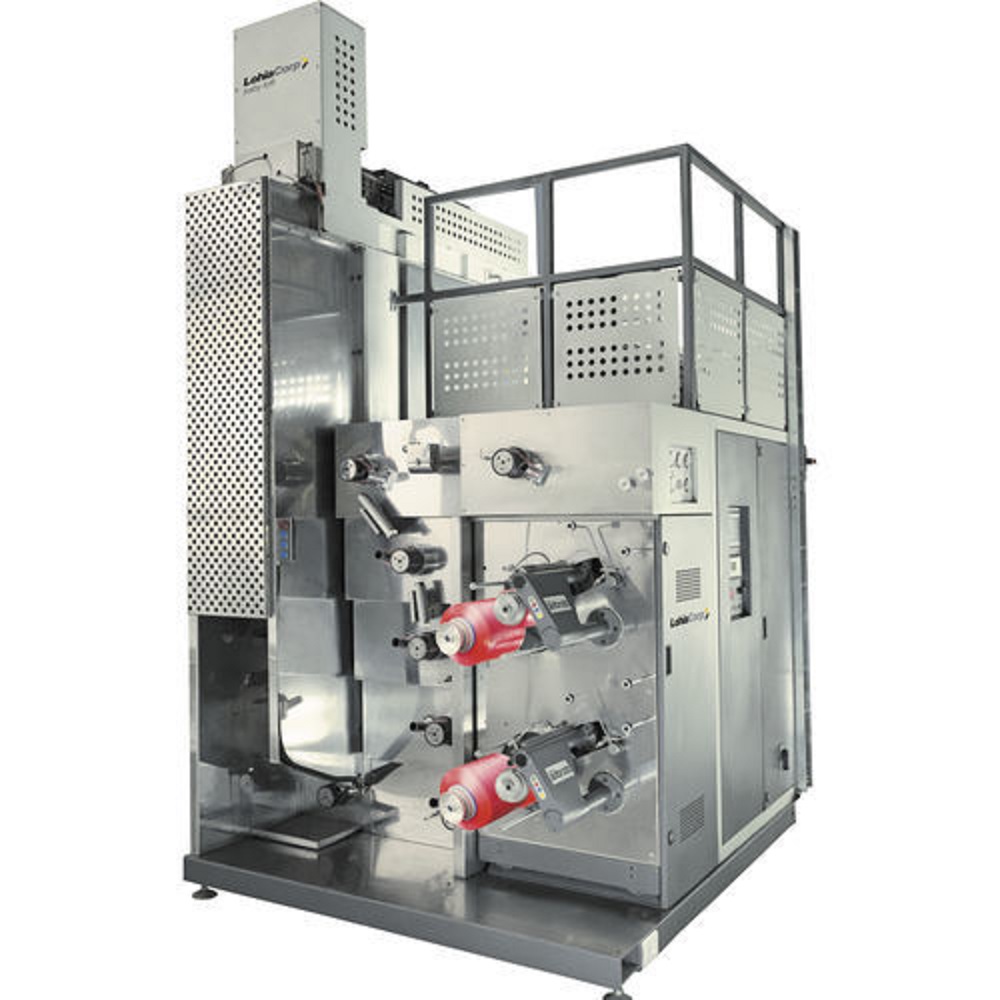

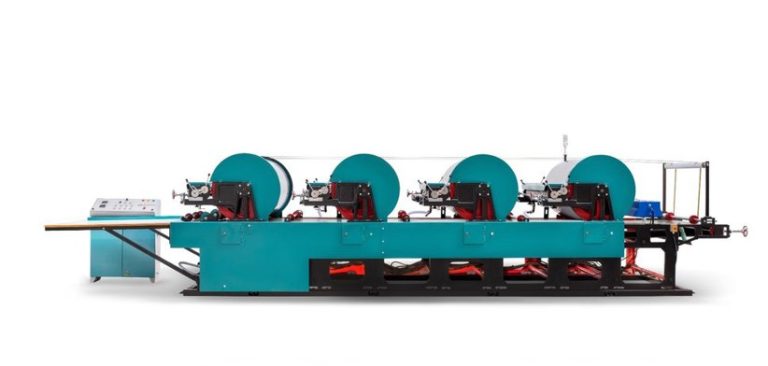

6.Printing

- Printing Unit – I (4 Colour Flexographic Machine):

- Type: Flexographic Printing Machine (Offline)

- Max Width: 1300 mm

- Print Repeat: 500–1200 mm

- Speed: Up to 100 m/min

- Drying: Infrared + hot air combo

- Features: Micro registration, tension control, double-sided print capability

7.Bag Making Facility

- The facility is equipped with 4 advanced bag-making lines, capable of producing high-quality 50 metric tons FIBC bags with precision stitching and consistent finishing to meet global packaging standards.

8.Testing Laboratory

- Universal Tensile Tester (UTM):

- Capacity: 5 Ton / 50 kN

- Control: Digital or PC-based

- Tests: Fabric strength, seam strength, loop lift testing

- Compliance: ISO 21898, IS 14968, ASTM D5034

- Output: Real-time load vs. elongation graph, auto report generation

9.Final Packaging

- Includes bale pressing, palletized packing, and secure wrapping for safe handling and export. Customized packing as per client requirement. Ensures product safety during transit and compliance with international standards.

Certifications & Compliance

- ISO 14001:2015

- ISO 9001:2015

- ISO 22000

- BRC Certification

- and other relevant industry certifications.

We adhere to stringent international standards to ensure the highest quality and safety for our products.

Ready to partner with a trusted Indian FIBC bags manufacturer?

Our Products

Explore our products for insights into Indian FIBC Bags Manufacturers—discover innovative designs, sustainability practices, and industry trends shaping the future of bulk packaging solutions. Stay informed and ahead of the curve!